Our offer includes products for pouring industrial cement-based concrete floors – the price we offer is attractive, and the quality of service is at the highest level, as evidenced by positive feedback from our customers, both new and trusted, who have been working with us for years. We offer assistance in choosing the right materials for poured concrete floors, the advantages of which include high resistance to abrasion and weather conditions, including water.

Poured concrete flooring, as well as resin, epoxy or polyurethane floors, present excellent physical properties that translate into very good resistance to damage and at the same time long-term durability. We invite you to cooperate with us – at favorable prices we provide professional results of pouring work and performed on our products.

Floating and monolithic concrete screeds

We specialize in the production of the highest quality materials to assist in pouring floors, using the highest quality concrete mix, which, with all the desired mechanical properties, is also visually attractive. We work with many industrial flooring contractors who are familiar with our products and are able to bring out their maximum potential! The safety of use of floors made on Si-Tech flooring materials is determined primarily by the anti-slip layer, which reduces the risk of falling. In order to achieve the best aesthetic results, industrial polished concrete is most often used, while in order for floors to show even greater durability it is worth using professional fibers of polypropylene, polymer or steel.

Basically, it is the purpose of the industrial facility that determines the appropriate design of the concrete floor. This primarily concerns the impact on them of various factors including. among others, mechanical, humidity and temperature. Therefore, for its implementation, it is necessary to use low-shrinkage industrial concrete, produced on the basis of special cement with very high strength and high-quality mineral additives with adequate grain size and, importantly, without a large proportion of fly ash (maximum 30 kg/m³). A floor made of such concrete, additionally reinforced with polypropylene and steel concrete fibers is characterized by incomparably higher resistance to fatigue, impact, abrasion, corrosion, crack and crack formation, as well as tensile and compressive strength compared to traditionally used solutions (a slip layer of special polyethylene film without waterproofing properties is laid on the substructure, and then fibrobrete is made). “Floating” of fibrobrete allows it to work with maturation and temperature changes. The use of polypropylene fibers also increases resistance to subzero temperatures and aids in the care of concrete.

In some facilities, where it is difficult or impossible to pour a polished floating concrete floor due to height limitations, a monolithic floor that is bonded to the substructure with the so-called S100 bonding bridge (possibly an affordable epoxy construction resin Meteor Stone or Meteor Stone W backfilled with sand) is applicable. Note, however, that for this solution, the thickness of the top layer of the concrete screed must not be less than about 50 mm.

Monolithic floors – main differences and advantages

What is the difference between a poured base of polished industrial concrete and a monolithic floor? The former requires more time to achieve the right hardness when poured. The second is suitable for use just a few hours after being laid. It has a high resistance to mechanical damage, which makes intensive use possible. Its destinations are not only manufacturing plants, but also warehouse halls or large-area stores.

It is also necessary to note the most important advantages of the installation of monolithic poured floors. First of all, their implementation is trouble-free for uneven surfaces. They do not require prior application of industrial concrete screeds.

Our task is to meet the requirements of investors and managers of industrial facilities. We encourage you to get acquainted with the offer of polished screeds and monolithic floors realized by us and establish cooperation! Ask now about the price of pouring concrete.

Curing, waterproofing, expansion joint of industrial concrete floor

.

After a standard-compliant pour, the polished industrial concrete floor, the price of which is highly competitive at our company, should be properly cured (we offer silicon sprinkling Romix or Romix BL in many color variations), followed by impregnation depending on the requirements of the screed (we offer P100, P200, P300, PH100 or PHW100). After a month or so of using poured concrete pavement, be sure to place dilatation cord in the joints, then perform priming with, for example. using Dilatan Primer (we recommend its use for a weak, chalky substrate – if it is not problematic the use of primer is not necessary), and finally fill with flexible Dilatan sealer for concrete screeds.

Tested preparations for floor protection and care

The choice of preparations at different prices for the curing and waterproofing of poured floors must be well thought out. For example, heavily used polished industrial concrete requires increased resistance to abrasion and chemicals. A silicate dispersion-based impregnation concentrate will therefore be a good choice. It contributes to reducing the level of water evaporation of the screed, which is important for a newly poured floor.

In the case of industrial polished floors in intensive use, as well as the poured concrete surface on external roads, solvent-based impregnating and impregnating preparations work well. They reduce the absorbency of liquids and also improve frost resistance. They can be found at affordable prices in our assortment.

Inquire about cooperation

We invite anyone who is looking for the highest quality materials at the best prices for poured industrial concrete flooring to cooperate with us. We are concrete pouring specialists with years of experience in the market not only in theory, but also in practice. If you represent a company for poured concrete and industrial flooring, and not only contact us – we are also engaged in seeking inquiries for poured concrete and resin floors, and then passing them on to our contractors. We look forward to your contact!

Floor pouring – what does the price of the project depend on?

We prepare our offer according to individual order. The best-made flooring, i.e. poured and polished concrete flooring, the price of which can vary, must be matched to the purpose of the room or how the entire floor construction is made. When choosing materials for pouring, we take into account the load on the poured floor in later use, changing ambient temperatures, as well as the effect of UV rays on the structure of industrial concrete.

The price of pouring a polished concrete surface varies with the type of screed and the number of square meters of poured floor, as well as the potential difficulties on the job site. If you would like to learn more details and get a customized quote for your project, we encourage you to contact us directly now.

-

Romix - Silicone cement hardener

Romix - Silicone cement hardener

-

Romix BL - corrogate hardener for newly put into industrial flooring (with hardening-minding additive)

Romix BL - corrogate hardener for newly put into industrial flooring (with hardening-minding additive)

-

P100 - impregnating and curating preparate

P100 - impregnating and curating preparate

-

P200 - impregnating and curating preparate (with reduced sensor)

P200 - impregnating and curating preparate (with reduced sensor)

-

P300 - impregnating and curating solvent-based preparate

P300 - impregnating and curating solvent-based preparate

-

PHW100 - impregnating and curating paraffins-based preparate

PHW100 - impregnating and curating paraffins-based preparate

-

K100 - crosemain dispersion impregnate concentrate

K100 - crosemain dispersion impregnate concentrate

-

L100 Diamond - penetric, non-penetratic preparation based on lithium cremate and polyuretan

L100 Diamond - penetric, non-penetratic preparation based on lithium cremate and polyuretan

-

S100 - concrete layer of concrete elements

S100 - concrete layer of concrete elements

-

Sagraf - Fluid preparate of different concentration to protect different surfaces from graffiti

Sagraf - Fluid preparate of different concentration to protect different surfaces from graffiti

-

HB100 - penetrating, hybrydic impregnate for concrete

HB100 - penetrating, hybrydic impregnate for concrete

-

Si-Clean - Daily Washing and Conditioning Agent for Concrete and Resin Floors

Si-Clean - Daily Washing and Conditioning Agent for Concrete and Resin Floors

-

Si-Wax - polymer paste for resin and concrete floors

Si-Wax - polymer paste for resin and concrete floors

-

Si-Active Concrete Clean - basic cleaner for thorough cleaning and removal of tough dirt on concrete floors

Si-Active Concrete Clean - basic cleaner for thorough cleaning and removal of tough dirt on concrete floors

-

Dylatan - uniform polyurethane based sealant

Dylatan - uniform polyurethane based sealant

-

Dylatan Primer - preparate based on synthetic solution resins

Dylatan Primer - preparate based on synthetic solution resins

-

Polyethylene dilatation cord

Polyethylene dilatation cord

-

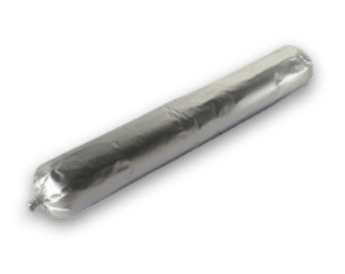

Polypropylene fiber for concrete

Polypropylene fiber for concrete

- Diamond discs

- Grinding discs